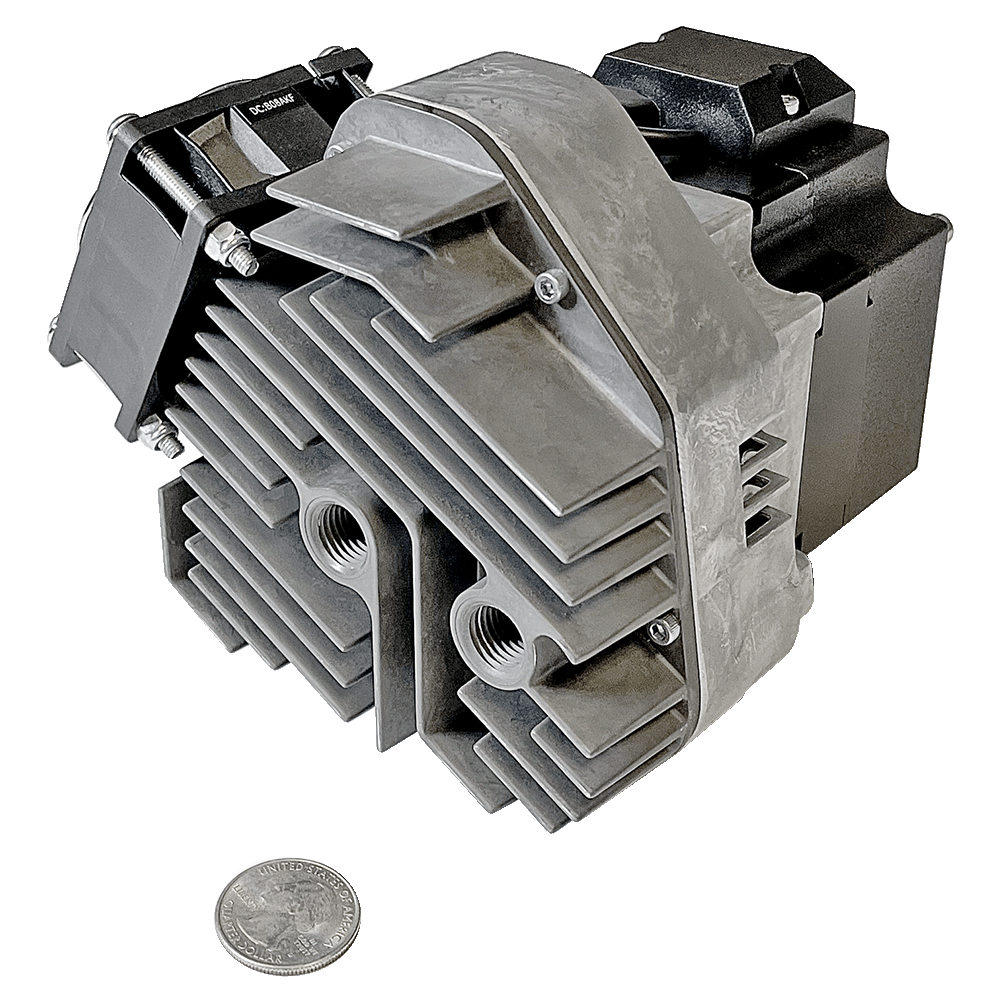

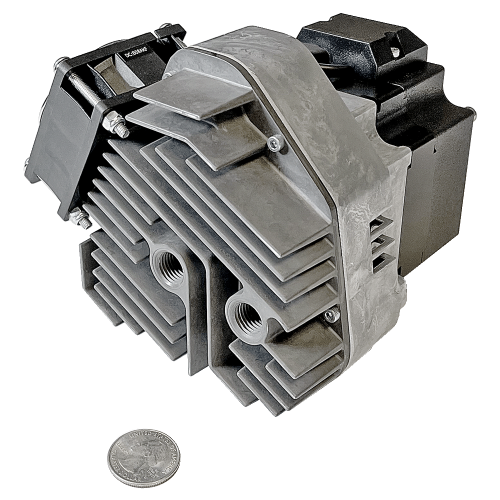

Silent Series Scroll Compressor

P09H017A-BLDC-C

Ultra-quiet, versatile, oil-free scroll compressor – ideal for a wide range of applications

- 100% Oil-Free

- Maintain the purity of your system with oil-free scroll technology

- Ultra-Quiet and Smooth Operation

- Dynamically balanced, valve-less, and nearly pulsation-free

- Compact and Lightweight Design

- Fewer moving parts than competing technology

- Efficient Performance

- Continuous compression process with no re-expansion or throttling losses

- Variable Speed

- Ideal performance over a range of duty cycles – 100% continuous to intermittent

SI

Imperial

Documentation

Available Accessories

- BLSD4850WDC Brushless DC Controller

- Mounting Feet

OEM Configurations

- Custom Mounting Bracket

- Custom Electrical Connector

- Custom Motor and Fan Voltage

- Custom Port Fittings

Qualified OEMs should contact Air Squared for custom configurations and application-specific requirements.

Related Articles

- Air Compressor Test Bench Schematic

- Air Compressor Testing Method

- Scroll Compressor and Vacuum Pump Efficiency

FAQS

P09H017A-BLDC-C

Most scroll compressors have a discharge port centered on the face of the unit, with the inlet port positioned near the periphery.

Most Air Squared products do not have a CE conformity marking.

Our products are primarily designed for OEMs and not intended for end users. As most OEM systems already require CE marking, conformity specific to an Air Squared product is generally not required.

OEM customers that require conformity specific to an Air Squared product should contact their Sales Representative.

Looking at the face of the unit, the motor shaft for scroll compressors and scroll vacuum pumps rotates clockwise.

Air Squared does not provide operation manuals for most products.

Given the specialized nature of our scroll products, Air Squared works directly with OEM customers to install, operate, test, evaluate, and service products. Customers who require an operation manual should contact their Sales Representative.

If you do not have a Sales Representative, start with our Application Assistant or contact Sales directly.

Monitoring speed is an important aspect of operating a scroll compressor or vacuum pump, as operation over the specified maximum speed can result in premature or catastrophic failure.

For scroll compressors and vacuum pumps that have a brushless DC motor, speed can be measured by connecting a digital tachometer between a hall sensor and ground. The tachometer must be programmed to the correct number of pulses per revolution, which can be determined by dividing the numbers of motor poles by 2. For example, an 8-pole motor will have 4 pulses per revolution.

Alternatively, an oscilloscope can also be used to measure the frequency of the hall sensors. Divide the measured frequency by the number of pulses per revolution and multiply by 60 to determine the RPM.

For scroll compressors and vacuum pumps that have an AC motor, speed can be measured by multiplying the frequency of the variable frequency drive (VFD) by 60 to determine the RPM.

General

Questions related to new or open invoices should be directed to Accounts Payable.

Contact Accounts Payable at +1 (303) 466-2669 or ap@airsquared.com.

Most domestic orders are not subject to sales tax.

Sales tax only applies to product(s) that ship inside Colorado, USA.

- Services, such as non-recurring engineering (NRE), are not subject to sales tax.

- Product(s) that ship outside of Colorado, USA are not subject to sales tax.

- Tax exempt organizations are not subject to sales tax. Tax exempt organizations that order a product(s) shipped within Colorado, USA must provide a sales tax license with their purchase order(s).

- Product(s) for resale are not subject to sales tax. Resellers that order a product(s) shipped within Colorado, USA must provide a sales tax license and indicate the product(s) is intended for resale on their purchase order(s).

Qualified customers can purchase sample unit(s) through their Sales Representative.

If you do not have a Sales Representative, start with our Application Assistant or contact Sales directly.

Air Squared does not currently offer products through any distribution networks.

Given the specialized nature of scroll technology, we only sell products direct to OEM customers from our facilities in Thornton, CO, USA. You can work directly with a Sales Representative to review requirements, select an appropriate solution, and arrange purchase.

If you do not have a Sales Representative, start with our Application Assistant or contact Sales directly.

Air Squared is ISO 9001:2015 and 14001:2015 certified.

Our formal quality program requires compliance to all customer needs and requirements in the area of product and service satisfaction. We understand some applications and markets require conformance to additional certifications – contact a Sales Representative to discuss your requirements in detail.

Purchase orders are sent directly to your Sales Representative.

If you do not have a Sales Representative, start with our Application Assistant or contact Sales directly.

Qualified customers can purchase sample unit(s) through their Sales Representative.

If you do not have a Sales Representative, start with our Application Assistant or contact Sales directly.

Air Squared does not currently have regional Sales Representatives.

Products are sold direct to OEM customers from our facilities in Thornton, CO, USA. You can work with a Sales Representative to review requirements, select an appropriate solution, and arrange purchases.

If you do not have a Sales Representative, start with our Application Assistant or contact Sales directly.

Air Squared currently has no plan to add distribution partners or external sales representation.

P09H017A-BLDC-C Products

P09H017A-BLDC-C Projects

The information presented in this material is based on technical data and test results of nominal units. It is believed to be accurate and reliable. Air Squared does not warrant, guarantee, or assume liability in connection with this information. Picture, Performance, Dimensions, and Electrical information for reference use only. Application conditions may adversely affect performance and product life. It is the responsibility of the user to determine the suitability of the product for intended use.