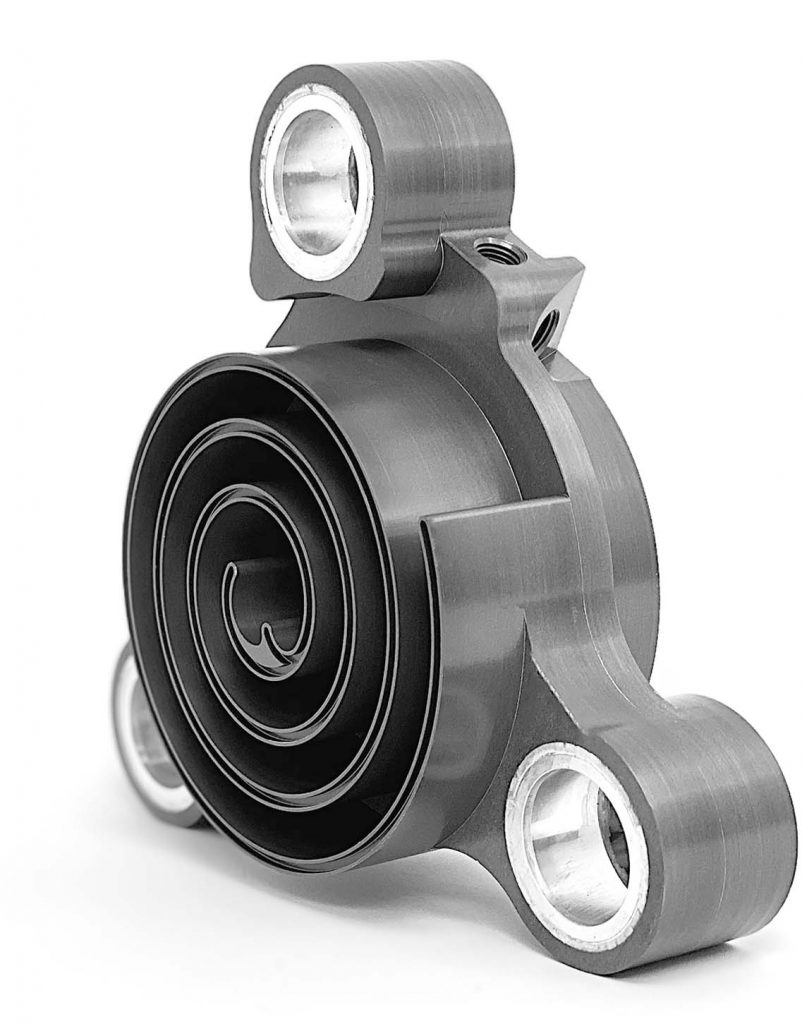

Semi-Hermetic Scroll Technology

Overview

Semi-hermetic scroll technology allows oil-free scroll designs to be compatible with numerous gases by incorporating one of four unique sealing configurations.

Leveraging over thirty years of scroll design experience, Air Squared has developed proprietary semi-hermetic configurations that are safe and compatible with a wide range of working fluids.

Range Technical Overview

Design Experience Range

Product Line Coverage

Semi-Hermetic Scroll Technology

Introduction

Scroll designs may be classified as being either open, semi-hermetic, or hermetic, depending on the features used to seal the working fluid from ambient.

An “open scroll” refers to a scroll design that has a vented housing and no sealing features. The exposed housing allows for adequate air cooling and circulation, but typically, the design is only suitable for operation with air.

A “hermetic scroll” refers to a scroll design that is completely sealed from ambient. Common in the refrigeration industry, hermetic sealing is usually accomplished by housing the scroll assembly and motor in a welded canister, fully containing the working fluid. Designs typically require lubrication and service is limited.

As is the case with all-metal scroll technology, a scroll design that uses metal O-rings to seal all static surfaces may also be considered “hermetic.”

A “semi-hermetic scroll” refers to a scroll design that is sealed from ambient using static O-rings. Air Squared has four unique semi-hermetic scroll configurations.

- Each configuration contains the working fluid differently. The appropriate configuration is typically selected based on compatibility with the list of wetted materials.

- Each configuration is ideal for oil-free operation, but when necessary for compatibility, modifications for lubricated operation are usually possible.

- Each configuration may incorporate air cooling or liquid cooling. The appropriate cooling configuration is typically selected based on the amount of heat expected to be generated during operation.

- Each configuration may be constructed using alternate materials, such as stainless steel or cast iron, when necessary for compatibility, but usually, aluminum construction is used.

A semi-hermetic scroll design is similar to a hermetic scroll design in that it offers sealing from ambient suitable for most working fluids (even leaky gases like helium), but it is also serviceable like an open scroll design, allowing for simplified maintenance.

Semi-Hermetic Scroll Technology

Configurations

Air Squared uses four primary semi-hermetic configurations: sealed housing, canned motor, magnetic coupling, and bellows. Each scroll configuration isolates the working fluid differently and in turn, has different wetted materials.

-

- -

- Static Sealing to Ambient

- No Wetted Motor

- No Wetted Rotor

- No Wetted Bearings

- No Wetted Tip Seals

Open

- Standard Oil-Free

- Learn More

Semi-Hermetic

- Sealed

Housing

- Canned

Motor

- Magnetic

Coupling

- Belows

Hermetic

- All-Metal

- Learn More

Semi-Hermetic Scroll Technology

How It Works

Sealed Housing Configuration

All components are packaged in a sealed housing and the motor is either integrated into the sealed housing or a sealed motor is attached to the housing. Static O-rings are used throughout the design to seal all surfaces.

Canned Motor Configuration

All components are packaged in a sealed housing and a canister is installed between the motor rotor and stator, separating the stator from the working fluid. Static O-rings are used throughout the design to seal all surfaces.

Magnetic Coupling Configuration

All components are packaged in a sealed housing and a magnetic coupling is used to adapt the motor to the housing, separating the motor from the working fluid. Static O-rings are used throughout the design to seal all surfaces.

Bellows Configuration

A flexible bellows with static O-rings is installed between the fixed scroll and orbiting scroll, separating the bearings, motor, and all other components from the working fluid.

-

- -

- AIR

- CO2

- CO

- N

- Ar

- He

- SF6

- REFRIGERANT

- H2

- O2

- NATURAL GAS

- CH4

- NH3

- STEAM

- TRITIUM

Open

- Standard Oil-Free

Semi-hermetic

- Sealed

Housing - *

- Canned

Motor - *

- *

- *

- *

- Magnetic

Coupling - *

- *

- *

- *

- *

- Belows

Hermetic

- All-Metal

- Recommended Configuration

- Compatible Configuration

- Non-Compatible Configuration

- Requires Special Bearings or Bearing Grease for Compatibility

Semi-Hermetic Scroll Technology

Advantages

Semi-hermetic scroll technology makes the numerous advantages of oil-free scroll technology available for operation with gases other than air.

Air Squared uses a non-contacting scroll configuration that requires zero lubrication – no contamination, no filter, no pump, just clean air without the impurities of oil.

Semi-hermetic scroll technology from Air Squared has no dynamic seals, allowing for compatibility with a wide range of working fluids and minimal leakage to ambient.

Semi-hermetic scroll technology is considerably quieter and smoother than traditional reciprocating technology.

The scroll geometry delivers continuous flow and eliminates the need for valves, resulting in significantly less port pulsation and associated valve noise. The unique orbital motion is dynamically balanced, minimizing vibration and reducing rubbing velocity far below piston rings.

The scroll compression process has minimal re-expansion losses – a problem found in reciprocating machines with every piston stroke – greatly improving volumetric efficiency. Throttling losses are also nonexistent with the valveless design.

Semi-hermetic scroll technology is durable and robust, with 70% fewer moving parts than reciprocating technology. With only two primary components, the scroll design is highly reliable and easily serviceable.