Oil-Free Scroll Technology 101

Advanced by Air Squared for Over Thirty Years

Oil-Free Scroll Technology

Overview

Not familiar with oil-free scroll technology? This is the best place to start for a basic understanding of the technology behind Air Squared.

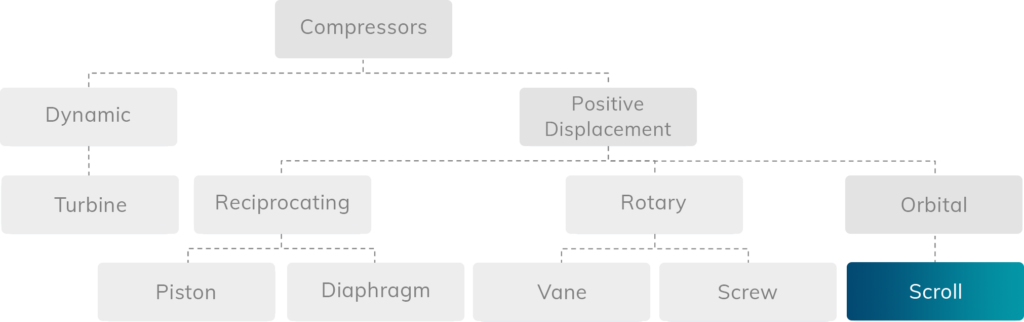

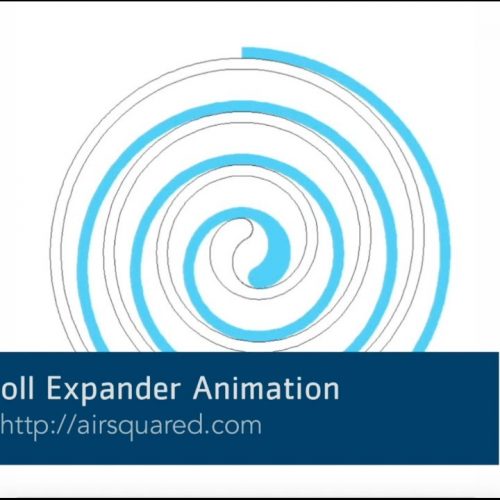

What is scroll technology? It’s the common technology behind scroll-type compressors, vacuum pumps, and expanders. They are generally defined as positive displacement devices having orbital motion and interleaving scrolls used to compress, pump, or expand fluids. Sound complicated? It actually isn’t. In fact, scroll-type devices are often referred to informally as “the elegant solution,” due to their simplistic design and quiet, smooth operation

Range Technical Overview

Design Experience Range

Product Line Coverage

Oil-Free Scroll Technology

History

The scroll concept is actually quite old. The initial patents date back to the early 1900s. Unfortunately, the technology to fabricate scrolls accurately did not exist, and the concept was forgotten.

In 1972 the scroll concept was re-invented by a physicist named Niels Young. Mr. Young brought the idea to Arthur D. Little, LLC of Cambridge, MA. Arthur D. Little saw its potential and began the development of a feasibility model in January 1973.

With pressure to significantly improve refrigeration compressor efficiency, the potential and advantages of a scroll compressor were recognized by the refrigeration industry in the mid-1970s. A scroll compressor offered improved efficiency, with the added benefit of greater reliability, smoother operation, and lower noise. Arthur D. Little began the development of a scroll-type compressor for refrigeration for the Trane Co. in late 1973.

Today, scroll compressors are used extensively for refrigeration by many well-known companies, including Trane, Hitachi, and Copeland.

1905

Léon Creux awarded first scroll patent

1972

Scroll concept re-invented by physicist Niels Young

1973

Niels Young, John McCullough, and Robert Shaffer begin scroll compressor research at Arthur D. Little

1981

Sanden begins manufacturing the first scroll compressor

1983

Emerson-Copeland, the largest scroll producer in the world today, begins manufacturing their first scroll design

1991

Robert Shaffer founds Air Squared, LLC in Cincinnati, OH, with the goal of developing and licensing compressor technology in various market areas

2001

Robert Shaffer and Mike Mansdorfer found Air Squared Manufacturing, LLC in Colorado, USA with the goal of mass-producing unique oil-free scroll compressor and vacuum pump designs for OEMs.

2021

A compact scroll compressor developed by Air Squared operates perfectly on the surface of Mars, helping convert carbon dioxide into oxygen as part of the Mars Oxygen In-Situ Resource Utilization Experiment onboard the Perseverance rover.

Oil-Free Scroll Technology

How it Works

Basic Principles of Operation

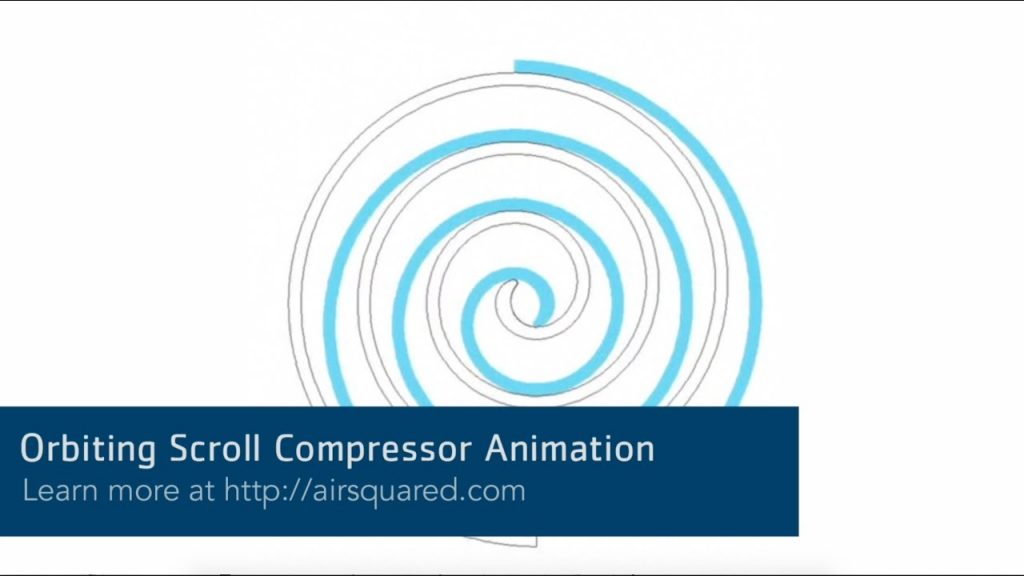

The two primary components, a “fixed scroll” and an “orbiting scroll,” are and the namesake of scroll-type designs. One scroll is index 180º with respect to the other, allowing the two scrolls to mesh together. The orbiting scroll is coupled to a crankshaft and orbits eccentrically, following a fixed path with respect to the fixed scroll.

During operation, a series of crescent-shaped pockets are created between the two scrolls. In the case of a scroll compressor, the working fluid moves from the periphery (inlet) towards the center (discharge) through increasingly smaller pockets, generating compression.

Similar principles apply for a scroll vacuum pump and a scroll expander.

Design and Construction

Involute geometry is complex, the design itself is not

Informally referred to as “the elegant solution,” standard oil-free scroll designs are simplistic and have few primary moving parts.

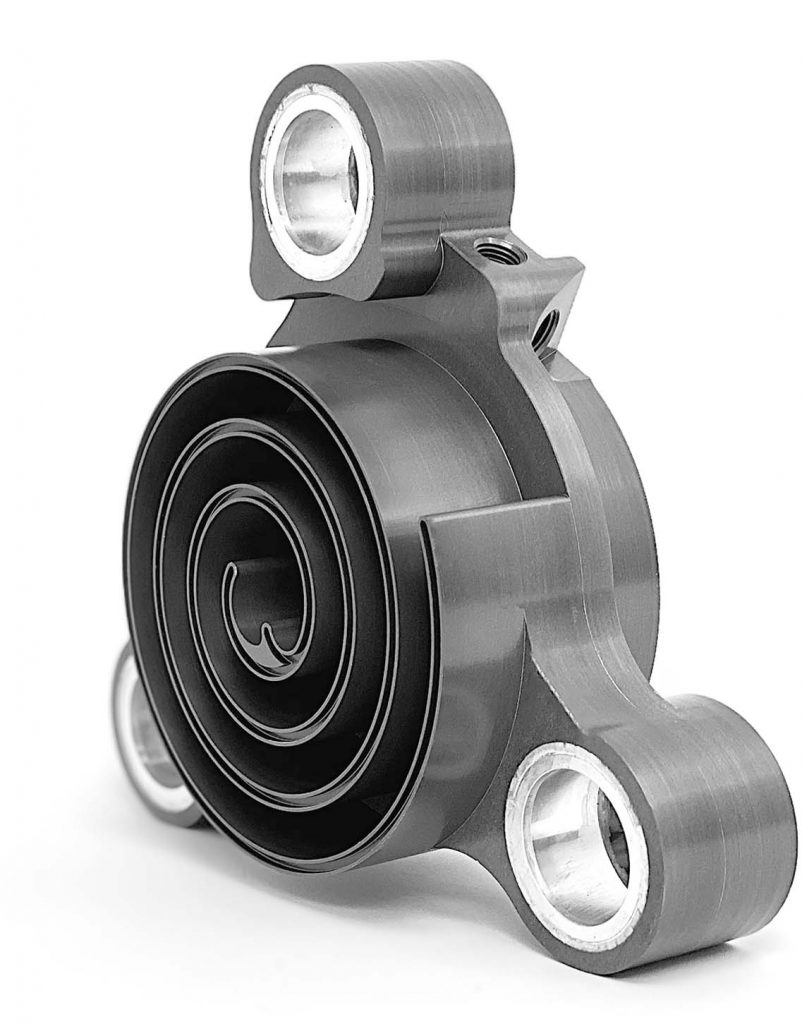

The “scroll pack” assembly is the heart of the design and consists of all primary and wearing components.

- The primary components are the fixed scroll, orbiting scroll, and three idler shafts that secure the position of the orbiting scroll relative to the fixed scroll.

- The wearing components are two tip seals, installed in the fixed scroll involute and orbiting scroll involute, and bearings around each idler shaft (“idler bearings”) and in orbiting scroll (“drive bearing”).

The “drive” assembly consists of a housing, motor, and crankshaft that drives the scroll pack. Most designs will also include a mounted fan for air cooling during operation.

Scroll Involute Sizing

The scroll involute geometry directly influences all performance parameters of the design. The primary design parameters of any scroll device are volume ratio and suction volume. The required pressure ratio and flow rate define the necessary volume ratio and suction volume.

Suction Volume

The Volume of gas entering the inlet of the involutes every revolution

A higher flow rate requires a larger suction volume (at a fixed speed).

A larger suction volume requires an increase of involute height, pitch, or both.

An increase of involute height increases a design’s axial length, while an increase of involute pitch increases a design’s diameter.

Volume Ratio

The ratio of inlet (suction) volume to the discharge volume

A higher pressure ratio requires a larger volume ratio.

A larger volume ratio requires an increase of involute wraps.

An increase of involute wraps increases a design’s diameter.

Oil-Free Vs. Lubricated

While the fundamental operating principles of an oil-free scroll and lubricated scroll are the same, there are significant differences in their respective designs. Lubricated scroll designs typically use an Oldham ring configuration. Alternatively, oil-free scroll designs typically use an idler shaft arrangement.

Lubricated scroll designs are more common, with millions of compressors manufactured for the refrigeration industry. The presence of oil during operation increases the running clearance between the fixed scroll and orbiting scroll, allowing for more open machining tolerances, which in turn, reduces cost. Additionally, the preferred driving method for the lubricated scroll is an Oldham ring, which requires lubrication, but is an inexpensive solution for maintaining the relative motion of the orbiting scroll.

Oil-free scroll designs are less common and more challenging to manufacture. Without the presence of oil, a close running clearance between the fixed scroll and orbiting scroll is required, as well as very tight machining tolerances. Unlike a “floating” Oldham ring configuration, Air Squared primarily uses an idler shaft configuration to maintain the relative motion of the orbiting scroll. The idler shaft arrangement allows for precise control over the running clearance, delivering efficient operation even without lubrication.

Oil-Free Scroll Technology

Advantages

With several advantages, oil-free scroll technology continues to replace traditional reciprocating, diaphragm, and vane technology in a variety of applications.

Air Squared uses a non-contacting scroll configuration that requires zero lubrication – no contamination, no filter, no pump, just clean air without the impurities of oil.

Scroll technology is considerably quieter and smoother than traditional reciprocating, diaphragm, and vane technology.

The scroll geometry delivers continuous flow and eliminates the need for valves, resulting in significantly less port pulsation and associated valve noise. The unique orbital motion is dynamically balanced, minimizing vibration and reducing rubbing velocity far below piston rings or vanes.

Air Squared uses a simplistic scroll design approach, with few moving parts and lightweight aluminum construction. Variable speed operation allows space-constrained applications to maximize performance by running at higher speed.

Scroll technology has minimal re-expansion losses – a problem found in reciprocating machines with every piston stroke – greatly improving volumetric efficiency. Throttling losses are also nonexistent with the valveless design.

Scroll technology is durable and robust, with 70% fewer moving parts than reciprocating technology. With only two primary components, the scroll design is highly reliable and easily serviceable.

Oil-Free Scroll Technology

Applied Innovation

Liquid-Cooled Technology

Liquid-cooled scroll technology allows oil-free scroll compressors to operate at higher pressure ratios and managing elevated temperatures over a wide range of working fluids.

Semi-Hermetic Scroll Technology

Semi-hermetic scroll technology allows oil-free scroll designs to be compatible with numerous gases by incorporating one of four unique sealing configurations.

Spinning Scroll Technology

Spinning scroll technology allows scroll designs to operate at higher speeds, providing a substantial size and weight reduction.

Staged Scroll Technology

Silent Series™ scroll compressors from Air Squared provide unmatched sound levels, smooth operation, and 100% oil-free performance in a compact design.

Design Experience Range

Product Line Coverage

Oil-Free Scroll Refrigeration

Staged scroll technology from Air Squared allows for high vacuum capability in a compact and lightweight design - ideal for applications with challenging size and weight requirements.

Design Experience Range

Product Line Coverage

All-Metal Scroll Technology

All-metal scroll technology allows oil-free scroll designs to be compatible with virtually any working fluid, even radioactive, toxic, or corrosive gases.

Design Experience Range

Product Line Coverage

Oil-Free Scroll Technology

Learn More

Do your products have a CE marking?

Most Air Squared products do not have a CE conformity marking.

Our products are primarily designed for OEMs and not intended for end users. As most OEM systems already require CE marking, conformity specific to an Air Squared product is generally not required.

OEM customers that require conformity specific to an Air Squared product should contact their Sales Representative.

How do we measure speed?

Monitoring speed is an important aspect of operating a scroll compressor or vacuum pump, as operation over the specified maximum speed can result in premature or catastrophic failure.

For scroll compressors and vacuum pumps that have a brushless DC motor, speed can be measured by connecting a digital tachometer between a hall sensor and ground. The tachometer must be programmed to the correct number of pulses per revolution, which can be determined by dividing the numbers of motor poles by 2. For example, an 8-pole motor will have 4 pulses per revolution.

Alternatively, an oscilloscope can also be used to measure the frequency of the hall sensors. Divide the measured frequency by the number of pulses per revolution and multiply by 60 to determine the RPM.

For scroll compressors and vacuum pumps that have an AC motor, speed can be measured by multiplying the frequency of the variable frequency drive (VFD) by 60 to determine the RPM.

In which direction does the motor rotate?

Looking at the face of the unit, the motor shaft for scroll compressors and scroll vacuum pumps rotates clockwise.

Where are the compressor inlet and discharge port?

Most scroll compressors have a discharge port centered on the face of the unit, with the inlet port positioned near the periphery.

Where can we find an operation manual?

Air Squared does not provide operation manuals for most products.

Given the specialized nature of our scroll products, Air Squared works directly with OEM customers to install, operate, test, evaluate, and service products. Customers who require an operation manual should contact their Sales Representative.

If you do not have a Sales Representative, start with our Application Assistant or contact Sales directly.