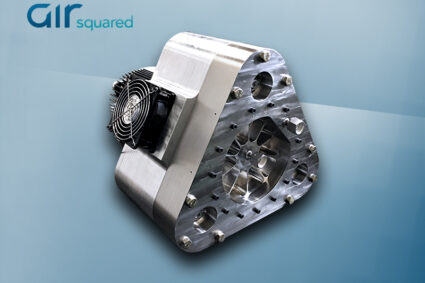

All-Metal Scroll Technology

Overview

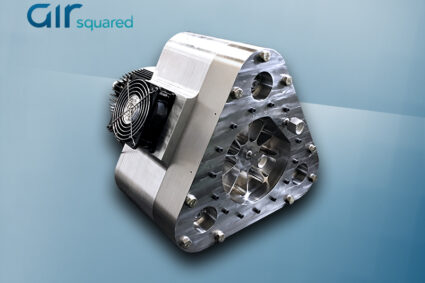

All-metal scroll technology allows oil-free scroll designs to be compatible with virtually any working fluid, even radioactive, toxic, or corrosive gases.

Hermetically sealed with only metallic and corrosion-resistant wetted parts, all-metal scroll technology allows for a wide range of fluid compatibility, including highly corrosive or high-temperature gases, as well as applications that require zero contamination and leakage, such as processing radioactive tritium.

While primarily used for vacuum operation, all-metal scroll technology can also be used to compress unique working fluids with adequate cooling.

Range Technical Overview

Design Experience Range

Product Line Coverage

All-Metal Scroll Technology

How It Works

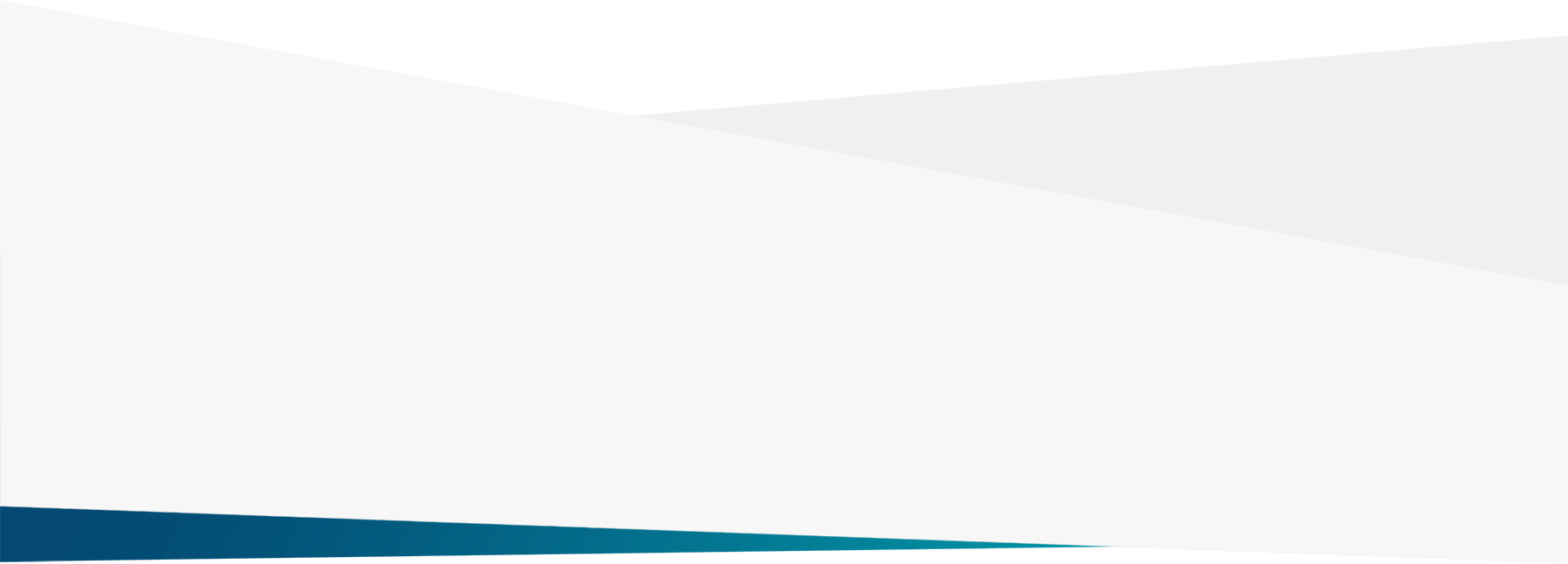

All-metal scroll technology uses a novel bellows configuration to hermetically seal and isolate the working fluid, allowing for safe operation with virtually any working fluid.

A stainless steel bellows with static metal O-rings is used to fully encapsulates the fixed scroll involute and the orbiting scroll involute. The bellows isolates the compression, vacuum, or expansion process from all other components, providing hermetical sealing and ensuring the working fluid is only in contact with metallic components.

If used in conjunction with liquid cooling, additional hermetic or semi-hermetic barriers can be used to further contain the working fluid.

All-metal scroll technology does not require the polymer-based tip seals common to oil-free scroll designs. With the removal of the tip seals, the working fluid is only in contact with metallic components (i.e., fixed scroll, orbiting scroll, O-rings, and bellows), allowing for compatibility with virtually any working fluid.

Without the use of tip seals, performance is maintained by holding an extremely tight running clearance between the fixed scroll and orbiting scroll. Effective thermal management using air or liquid cooling is critical, as it prevents thermal expansion and in turn, dimensional changes to the fixed scroll and orbiting scroll.

The isolated compression process consists of two nickel-boron-coated aluminum scrolls and a stainless steel bellows, providing corrosion resistance and compatibility with a broad range of working fluids.

All-Metal Scroll Technology

Advantages

All-metal scroll technology offers specialized applications a solution that is hermetically sealedand compatible with radioactive, toxic, or corrosive gases.

Air Squared uses a non-contacting scroll configuration that requires zero lubrication – no contamination, no filter, no pump, just clean air without the impurities of oil.

All-metal scroll technology from Air Squared has no dynamic seals and only metallic wetted componentry, allowing for compatibility with virtually any working fluid.

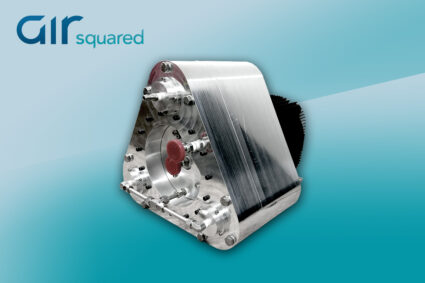

The scroll geometry delivers continuous flow and eliminates the need for valves, resulting in significantly less port pulsation and associated valve noise. The unique orbital motion is dynamically balanced, minimizing vibration and reducing rubbing velocity far below piston rings.

All-metal scroll technology is durable and robust, with 70% fewer moving parts than reciprocating technology. With only two primary components, the scroll design is highly reliable and easily serviceable.

All-metal scroll technology can be used as a “drop-in” replacement for legacy Normetex vacuum pumps in tritium processing applications.

Using an improved housing design and scroll configuration, all-metal scroll technology from Air Squared offers a 40% weight reduction over comparable hermetic vacuum pumps, allowing for easier installation and maintenance.