Liquid-Cooled Series

Products

Liquid-Cooled Series™ scroll compressors from Air Squared make the quiet, smooth, and efficient performance of oil-free scroll technology available for high-pressure operation.

Liquid-Cooled Series

Advantages

Liquid-Cooled Series™ scroll compressors offer OEMs a quiet, smooth-operating, and reliable alternative to traditional reciprocating compressors and air-cooled scroll compressors.

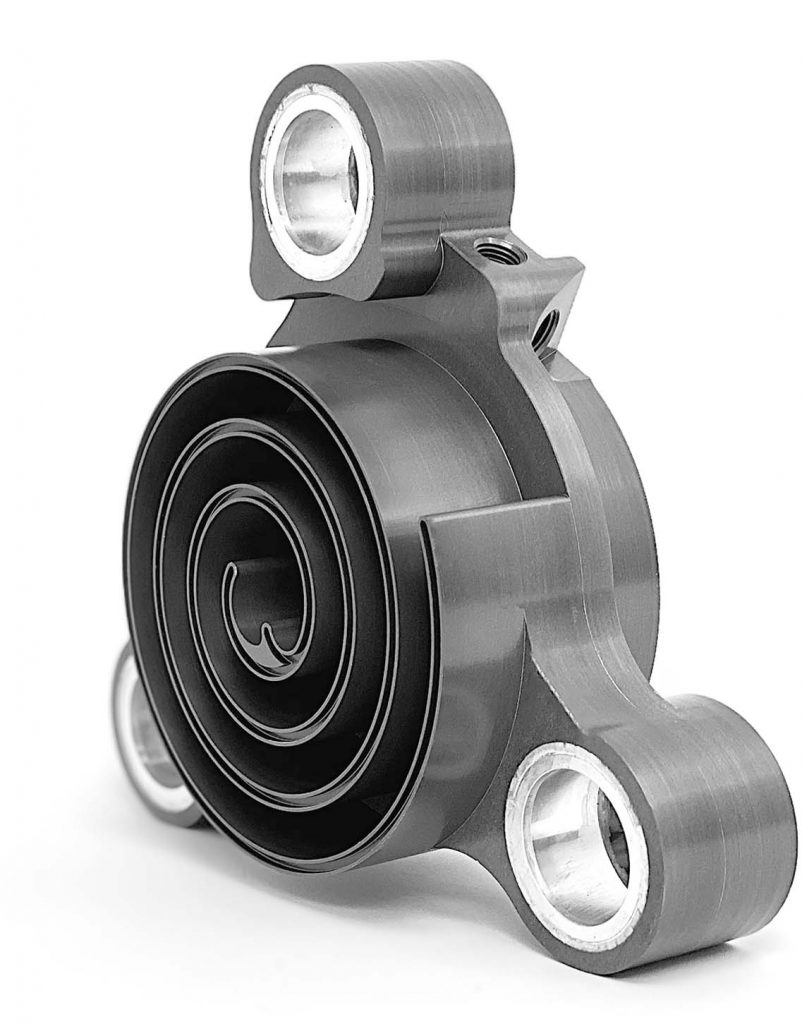

Air Squared uses a non-contacting scroll configuration that requires zero lubrication – no contamination, no filter, no pump, just clean air without the impurities of oil.

Liquid-cooled scroll technology is considerably quieter and smoother than traditional reciprocating technology.

The scroll geometry delivers continuous flow and eliminates the need for valves, resulting in significantly less port pulsation and associated valve noise. The unique orbital motion is dynamically balanced, minimizing vibration and reducing rubbing velocity far below piston rings or vanes.

Additionally, because liquid-cooled scroll designs do not require ambient air to directly cool the fixed scroll and orbiting scroll, the housing is enclosed and fan noise is eliminating, reducing sound levels even below that of air-cooled scroll designs.

Air Squared uses a simplistic scroll design approach, with few moving parts and lightweight aluminum construction.

Additionally, because liquid-cooled scroll designs do not require ambient air to directly cool the fixed scroll and orbiting scroll, several auxiliary components (e.g., cooling fins, fans, ducting) are no longer necessary, allowing for a compact design with a minimal footprint.

Liquid-cooled scroll technology has minimal re-expansion losses – a problem found in reciprocating machines with every piston stroke – greatly improving volumetric efficiency. Throttling losses are also nonexistent with the valveless design.

Additionally, by introducing effective cooling directly to the fixed and orbiting scroll, internal running clearances can be reduced compared to air-cooled designs, significantly improving efficiency.

Liquid-cooled scroll technology allows all components to be arranged in an enclosed housing, providing ideal immersion protection for applications with harsh environmental conditions.

Liquid-cooled scroll technology is durable and robust, with 70% fewer moving parts than reciprocating technology. Liquid-cooling provides a thermal barrier between the compression process and bearings, significantly improving bearings life and with only two primary components, the design is highly reliable and easily serviceable.