Oil-Free Scroll Refrigeration

Overview

Oil-free scroll refrigeration technology makes the numerous advantages of oil-free scroll compressors available for vapor-compression refrigeration applications.

The technology provides an efficient and compact refrigeration compressor solution that does not require any lubrication, making it ideally suited for aerospace and space refrigeration applications where a zero-gravity or hypergravity environment make oil circulation challenging.

Range Technical Overview

Design Experience Range

Product Line Coverage

Oil-Free Scroll Refreigeration

How It Works

Design and Construction

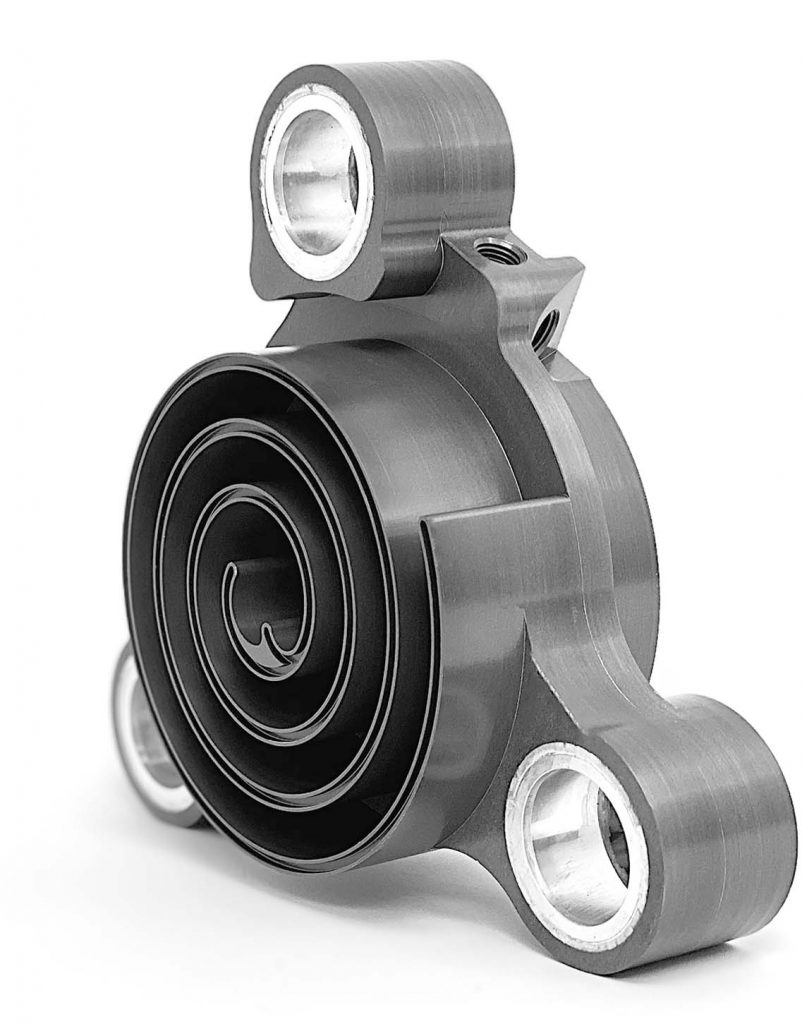

Oil-free scroll refrigeration designs are similar to other oil-free scroll designs, but use semi-hermetic sealing features to reduce leakage and isolate the greased bearings for minimal contact with the working fluid.

Scroll compressors used throughout the refrigeration industry typically use an Oldham ring to maintain the relative motion of the fixed and orbiting scroll. The configuration is inexpensive at scale, but requires lubrication during operation. Alternatively, oil-free scroll refrigeration compressors use an idler shaft arrangement that does not require lubrication to maintain the relative motion between the fixed and orbiting scrolls.

Oil-Free Vs. Lubricated

While the fundamental operating principles of an oil-free scroll and lubricated scroll are the same, there are significant differences in their respective designs. Lubricated scroll designs typically use an Oldham ring configuration. Alternatively, oil-free scroll designs typically use an idler shaft arrangement.

Lubricated scroll designs are more common, with millions of compressors manufactured for the refrigeration industry. The presence of oil during operation increases the running clearance between the fixed scroll and orbiting scroll, allowing for more open machining tolerances, which in turn, reduces cost. Additionally, the preferred driving method for the lubricated scroll is an Oldham ring, which requires lubrication, but is an inexpensive solution for maintaining the relative motion of the orbiting scroll.

Oil-free scroll designs are less common and more challenging to manufacture. Without the presence of oil, a close running clearance between the fixed scroll and orbiting scroll is required, as well as very tight machining tolerances. Unlike a “floating” Oldham ring configuration, Air Squared primarily uses an idler shaft configuration to maintaining the relative motion of the orbiting scroll. The idler shaft arrangement allows for precise control over the running clearance, delivering efficient operation even without lubrication.

Oil-Free Scroll Refrigeration

Advantages

Oil-free scroll refrigeration offers an oil-free alternative to traditional lubrication scroll and piston refrigeration compressors.

Air Squared uses a non-contacting scroll configuration that requires zero lubrication – no oil “pooling” and no oil management system needed.

With no oil circulation required, oil-free scroll refrigeration compressors can operate continuously in any orientation, in zero-gravity and variable-gravity environments, undergoing acceleration changes.

The semi-hermetic scroll configuration uses static seals for compatibility with refrigerants while allowing the design to be easily serviceable.

With no oil film that reduces heat transfer, oil-free scroll refrigeration systems have an improved refrigeration-side heat transfer coefficients.

Oil-free scroll refrigerator compressors are reliable, durable, and tolerant to liquid flooding.

Oil-Free Scroll Refrigeration

Custom Design and Development

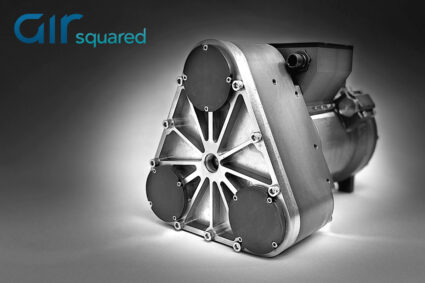

With an ever-expanding range of design capabilities for unique requirements, Air Squared has the experience to apply oil-free scroll refrigeration in your application.

Oil-Free Design

Oil-free scroll refrigeration technology offers an alternative to traditional lubricated refrigeration compressors.

Gases Other Than Air

With several patented semi-hermetic configurations, scroll compressors can be used for far more than moving air.

High-Efficiency

When minimal power consumption is critical, leverage the inherent efficiency advantage of scroll technology.

Compact Footprint

Unique scroll arrangements allow scroll designs to fit in small envelopes without sacrificing performance.