Air Squared News

Development of Zero-Gravity Refrigeration System Continues

Air Squared has been awarded Phase II Small Business Innovative Research (SBIR) funding from NASA to continue development of a Zero-Gravity Vapor-Compression Refrigerator (ZVCR) for space-bound food storage.

Broomfield, CO –Air Squared is one step closer towards developing another innovation for the commercial space industry with Phase II Small Business Innovative Research (SBIR) funding for a Zero-Gravity Vapor-Compression Refrigerator (ZVCR) from the National Aeronautics and Space Administration (NASA). The Phase II SBIR award will allow Air Squared to fabricate and test a full-scale prototype in 2019 and a second generation prototype in 2020.

The award follows a solicitation by NASA a Phase I SBIR award to increase cold-storage volume without compromising efficiency. State-of-the-art systems on the International Space Station (ISS) have a coefficient of performance (COP) of 0.36. The ZVCR increases cold storage volume while maximizing overall efficiency, allowing for terrestrial cold-storage efficiencies in zero-gravity.

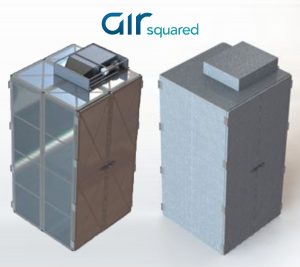

The primary goal of the Phase II effort is to demonstrate a full-scale prototype ZVCR that meets or exceeds a COP of 3.5. While vapor-compression cold-storage is typical of modern refrigerators, incorporating three scroll technology innovations from Air Squared could make the ZVCR an ideal solution for space-bound systems:

- Oil-free scroll technology

- Multi-stage scroll technology

- Integrated scroll compressor and expander for expansion work recovery

Along with increasing the technology readiness level of the integrated scroll compressor and expander, the Phase II effort will help Air Squared further engineering heritage of scroll-based vapor-compression and thermal systems, allowing for additional terrestrial and space-bound applications in the future. Air Squared will partner with Herrick Labs at Purdue University throughout the effort and apply their extensive research in refrigeration systems to the ZVCR.

If the effort is successful, the next potential destination for the ZVCR is onboard the ISS for further testing at the Center for the Advancement of Science in Space (CASIS).

About Integrated Scroll Compressor-Expander Technology

With patented integrated scroll compressor-expander technology from Air Squared, the scroll compressor and expander operate on a common shaft, allowing a single semi-hermetic shell to be used for all rotating components. The work recovered by the expander can be directly transmitted to the compressor, significantly improving efficiency. The integration of the compressor and expander not only makes the system more compact but also requires fewer components, (e.g., bearings, generator), which in turn reduces system weight and improves reliability.

About Multi-Stage Scroll Technology

The purpose of the multi-stage scroll technology is to help reduce the overall footprint of the device, while providing the same performance, or better, of a single-stage device. Multi-stage technology can be configured to run in series, parallel, or both within the same unit.

The primary benefit of multi-stage scroll technology is that the device has the same number of moving parts as a traditional single-stage design. This is accomplished by machining an additional involute on the back side of the orbiting scroll and adding a mating scroll on the housing.

About Air Squared

Air Squared is the industry leader in oil-free scroll design and manufacturing. By introducing a simple design with fewer moving parts, scroll technology has established itself as a highly efficient, very reliable, cost-effective alternative. Through a growing line of compressors, vacuum pumps, and expanders, Air Squared makes the many advantages of oil-free scroll technology available to OEMs worldwide.

This material is based upon work supported by a Phase II SBIR award by the National Aeronautics and Space Administration under the subtopic: Logistics Reduction (H3.04). Any opinions, findings, conclusions, or recommendations expressed in this material are those of the author(s) and do not necessarily reflect those of the National Aeronautics and Space Administration.