Spinning Scroll Technology

Overview

Spinning scroll technology allows scroll designs to operate at higher speeds, providing a substantial size and weight reduction.

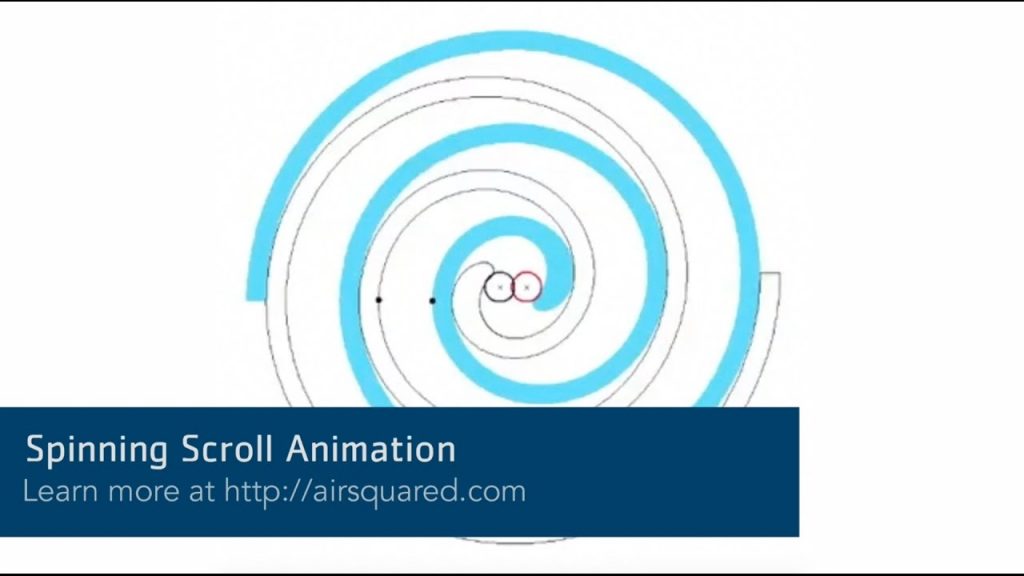

In a spinning scroll design (also referred to as a “co-rotating scroll”) the relative motion between the two mating scrolls is the same as an orbiting scroll design, but both scrolls rotating in synchronous motion with offset centers of rotation. The novel configuration allows for running speeds up to 8,000 RPM.

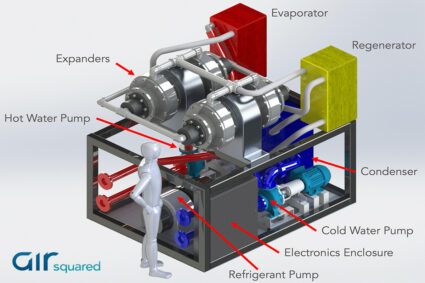

Air Squared has demonstrated spinning scroll compressors, as well as both oil-free and lubricated expanders. The technology is particularly well-suited for lubricated expander operation when used in a semi-hermetic design configuration.

Range Technical Overview

Spinning Scroll Technology

How It Works

Basic Principles of Operation

In a spinning scroll design, instead of one scroll remaining stationary (i.e., fixed scroll) while the other scroll orbits eccentrically (i.e., orbiting scroll) on a fixed path, two scrolls rotate in synchronous motion with offset centers of rotation.

During operation, the relative motion between the two mating scrolls is the same as an orbiting scroll design. Flow is generated in the same manner, with the relative motion between the scrolls creating a series of crescent-shaped gas pockets that generate pressure, vacuum, or expansion depending on how the device is being operated.

In a spinning scroll design, the simplified balancing and reduced componentry allow for higher obtainable running speeds by a factor of two or more (i.e., 6,000 to 8,000 RPM) when compared to an orbiting scroll design. As pressure and flow are directly proportional to speed, spinning scroll technology offers a substantial size and weight reduction.

Design and Construction

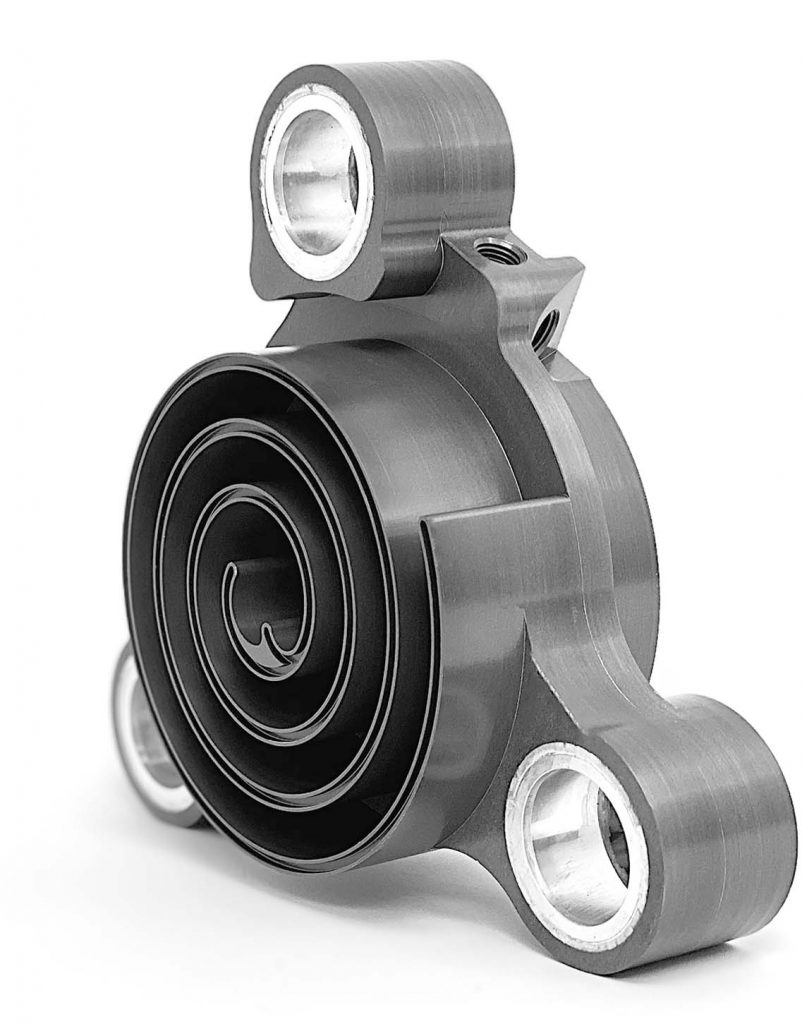

While scroll involute sizing and geometry are similar between a spinning scroll design and orbiting scroll design, a spinning scroll design requires less componentry.

In an orbiting scroll design, the discharge port is in the stationary scroll (i.e., fixed scroll). This configuration is not possible in a spinning scroll design, as both scrolls are in motion. Alternatively, the drive shaft provides an outlet for the working fluid while also holding the driven scroll on its axis of rotation.

As both scrolls rotate rather than one scroll orbiting, balancing is simplified. Instead of using a counterweight for balancing, the true rotary motion of the synchronous scrolls eliminates the need for counter-mass altogether, allowing for shorter and lighter drive shafts.

Spinning Scroll Technology

Advantages

When size and weight matter, spinning scroll technology offers a compact, lightweight, and highly efficient compressor and expander solution.

Air Squared uses a non-contacting scroll configuration that requires zero lubrication – no contamination, no filter, no pump, just clean air without the impurities of oil.

Spinning scroll technology is capable of running speeds twice as high as standard orbiting designs, allowing for significantly higher flow without increasing overall footprint or weight. The true rotary motion of the synchronous scrolls also eliminates the need for counterweights, allowing for shorter and lighter drive shafts.

Spinning scroll technology is considerably quieter and smoother than traditional centrifugal and vane technology.

The scroll geometry delivers continuous flow and eliminates the need for valves, resulting in significantly less port pulsation and associated valve noise. The unique spinning motion is perfectly balanced, minimizing vibration and reducing rubbing velocity.

Spinning scroll technology has minimal re-expansion losses and throttling losses are also nonexistent with the valveless design.

Spinning Scroll Technology

Custom Design and Development

With an ever-expanding range of design capabilities for unique requirements, Air Squared has the experience to apply spinning scroll technology in your application.

Ultra-Lightweight

Spinning scroll technology provides one of the lightest compressor and vacuum pump designs available.

Gases Other Than Air

With several patented semi-hermetic configurations, scroll designs can be used for far more than moving air.

Compact Footprint

Unique co-rotating scroll configurations allow scroll designs to fit in small envelopes without sacrificing performance.

Oil-Free Design

Oil-free scroll technology offers a non-lubricated alternative to traditional technology like piston, diaphragm, and vane.