Air Squared News

Spinning Scroll Expander Development Receives Navy STTR Award

Air Squared and Purdue University have been awarded Phase I Small Business Technology Transfer (STTR) funding to improve available power on naval vessels using waste heat recovery.

Broomfield, CO – Following the successful development of a 1 kWe spinning scroll expander completed under the GENSETS project, Air Squared and Purdue University have received Phase I STTR funding for the development of the High-Speed Spinning Scroll Expander (HiSSS-e) under the topic: Advanced Power Density Improvements to Electrical Generation Systems.

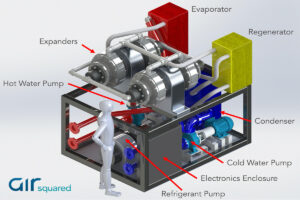

Designed to capture the exhaust from surface combatant Ship Service Diesel Generator Sets (SSDG), an HiSSS-e organic Rankine cycle (ORC) waste heat recovery (WHR) engine could potentially be powered by two sets of dual-spinning scroll expanders that produce up to 200 kWe of usable energy. Although the ORC would produce over twice the power of previous engines designed by Air Squared, the novel dual-spinning scroll design supports significantly higher speeds, achieving increased flow and power, while maintaining a minimal footprint.

As part of the Phase I effort, Air Squared has designed, fabricated and tested a 5 kWe spinning-scroll expander to demonstrate proof of concept. The primary objective was to develop a comprehensive ORC system model and test the scaled-down 5 kWe expander at speeds up to 8,000 RPM. The goals were to reduce the ORC system size and weight, while simultaneously increasing the available power, using patented spinning-scroll technology. With this success, a significant improvement in power density will help overcome key market obstacles that prevent the adoption of WHR technology in mobile applications.

The project was funded through the fourth quarter of 2019 and resulted in the world’s first and largest spinning scroll expander produced.

About Spinning Scroll Technology

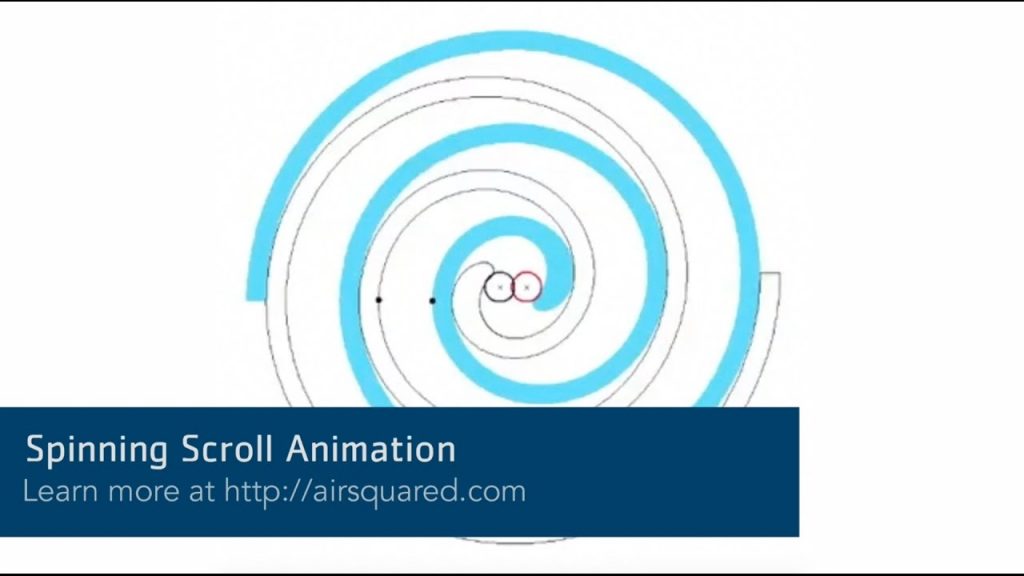

In principle, spinning scroll design (also referred to as a “co-rotating scroll”) is very similar to traditional orbiting scroll design, as the relative motion between the two scrolls is identical. Pressure and flow are generated the same in either approach, with the relative motion between scrolls creating a series of crescent-shaped gas pockets that generate pressure, vacuum, or expansion depending on how the device is being operated.

The primary difference is that the traditional approach of one scroll remaining stationary while the other scroll orbitseccentrically on a fixed path is replaced with two scrolls that simply rotate in synchronous motion with offset centers of rotation.

The spinning scroll approach reduces componentry, improves efficiency, and allows for higher running speeds. The true rotary motion of the synchronous scrolls eliminates the need for counterweights, allowing for shorter and lighter drive shafts, which in turn, reduces power consumption, size, and weight. The simplified balancing and a lighter drive configuration also allow for higher obtainable running speeds by a factor of two. As pressure and flow are directly proportional to speed, a spinning scroll design can offer similar performance, with substantial size and weight reduction.

About Air Squared

Air Squared is the industry leader in scroll expander design and manufacturing. By introducing a simple design with fewer moving parts, scroll technology has established itself as a highly efficient, very reliable, cost-effective alternative to traditional expanders. With a growing line of custom and commercial expanders, Air Squared makes the many advantages of scroll technology available to OEMs worldwide.

This material is based upon work supported by a Phase I STTR award by the US Navy under the topic: Advanced Power Density Improvements to Electrical Generation Systems (N19A-T013). Any opinions, findings, conclusions, or recommendations expressed in this material are those of the author(s) and do not necessarily reflect those of the US Navy.