Air Squared News

Spacesuit Spinning Scroll Boost Compressor Development Continues

Air Squared secures Phase II funding from NASA to fabricate and test a novel spinning scroll boost compressor (SSBC) for next-generation spacesuits.

Broomfield, CO – After successfully completing feasibility testing in 2019, Air Squared has received small business innovation research (SBIR) Phase II funding from NASA to continue the development of its pressure swing adsorption CO2 and H20-removal spinning scroll boost compressor (SSBC).

Following the topic Exploration Portable Life Support System (xPLSS) for deep space and surface missions (H4.01),” the SSBC is being developed as a key component in next-generation extra vehicular mobility unites (xEMU), better known as “spacesuits.” The novel compressor is being designed specifically to handle the Martian atmosphere.

As part of the Phase I effort, the SSBC was optimized to balance size, weight, noise, and vibration, while requiring as few components as possible. The Phase II effort will target improving two performance metrics:

- Utilizing patented spinning scroll architecture, achieve a running of speed of 8,000 RPM, reducing size and weight.

- Utilizing patented liquid-cooling, achieve pressure as high as 19.5 psia at flow rates over 600 lpm.

- Finalize SSBC design and solid model

SPINNING SCROLL TECHNOLOGY

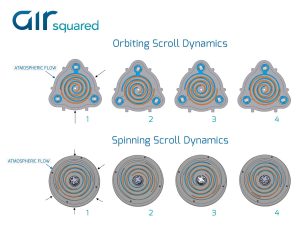

In principle, the design of the spinning scroll (also referred to as a “co-rotating scroll”) is very similar to that of the traditional orbiting scroll, as the relative motion between the two scrolls is identical. Pressure and flow are generated the same in both approaches, with the relative motion between the scrolls creating a series of crescent-shaped gas pockets that generate pressure, vacuum, or expansion depending on how the device is being operated.

The primary difference is that the traditional approach of one scroll remaining stationary while the other scroll orbitseccentrically on a fixed path is replaced with two scrolls that rotate in synchronous motion with offset centers of rotation.

The spinning scroll approach reduces componentry, improves efficiency, and allows for higher running speeds. The true rotary motion of the synchronous scrolls eliminates the need for counterweights, allowing for shorter and lighter drive shafts, which, in turn, reduce power consumption, size, and weight. The simplified balancing and a lighter drive configuration also allow for higher obtainable running speeds by a factor of two. As pressure and flow are directly proportional to speed, the spinning scroll design can offer a similar performance with substantial size and weight reduction.

This material is based upon work supported by a Phase II SBIR award by the National Aeronautics and Space Administration under the topic: Exploration Portable Life Support System (xPLSS) for Deep Space and Surface Missions (H4.01). Any opinions, findings, conclusions, or recommendations expressed in this material are those of the author(s) and do not necessarily reflect those of the National Aeronautics and Space Administration.