#Liquid-Cooled#Scroll-Compressor

Liquid-Cooled Scroll Technology

Designed and Developed by Air Squared

Liquid-Cooled Scroll Technology

Overview

Liquid-cooled scroll technology allows oil-free scroll compressors to operate at higher pressure ratios and managing elevated temperatures over a wide range of working fluids.

Integrating liquid cooling in an oil-free scroll design allows for significantly more control over operating temperatures throughout the compression process. By effectively managing thermal loads, an oil-free scroll compressor can operate reliably and efficiently at high discharge pressures and in high-temperature ambient environments.

Range Technical Overview

Design Experience Range

Product Line Coverage

Liquid-Cooled Scroll Technology

How It Works

Basic Principles of Operation

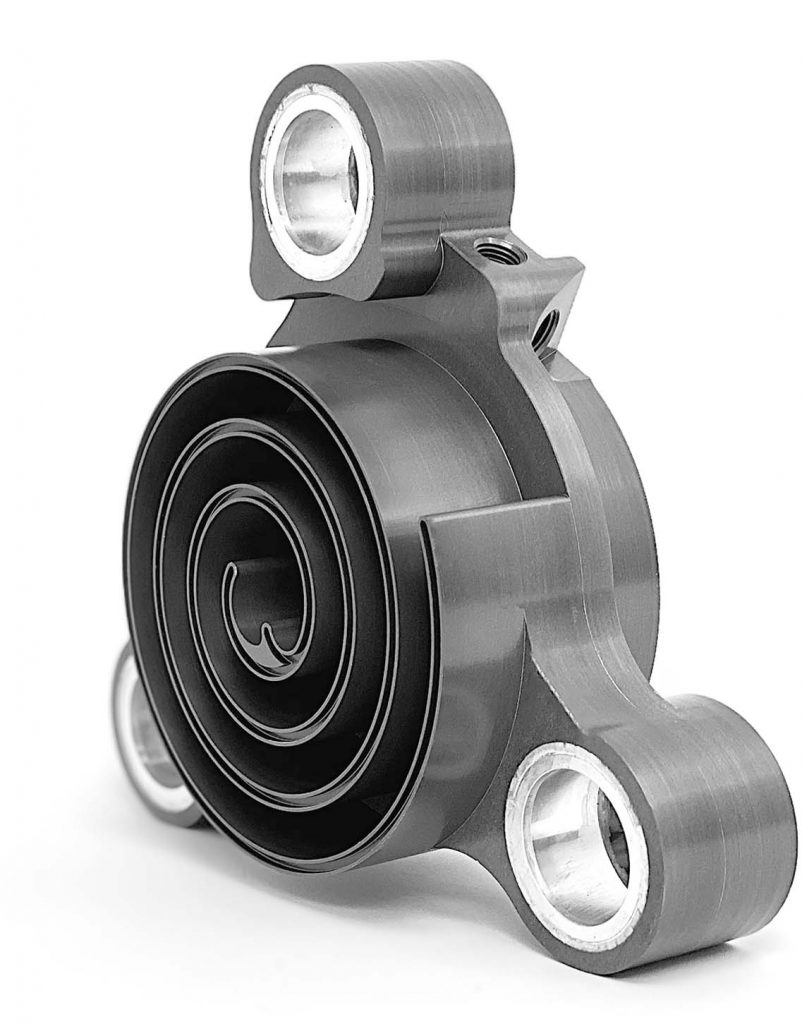

Oil-free scroll designs require a tight running clearance between the fixed scroll and orbiting scroll. With effective liquid cooling, the running clearance between the two primary components is more easily managed, allowing for efficient and reliable operation.

Operating temperature increases with pressure as heat is generated throughout the compression process. Without adequate cooling, elevated operating temperatures will cause the fixed scroll and orbiting scroll to thermally expand.

Air-cooled scroll designs are pressure-limited for this reason. Cooling is limited, so the primary working components are subject to thermal expansion, and in turn, interference between the fixed scroll and orbiting scroll. While the running clearance between the fixed scroll and orbiting scroll can be increased to avoid interference, this approach also decreases volumetric efficiency.

Liquid-cooled scroll technology solves this challenge by introducing liquid cooling to the fixed and orbiting scroll, allowing oil-free scroll compressors to operate at pressure ratios that are not possible with air cooling.

Design and Construction

Liquid-cooled scroll technology allows coolant to be transferred between the fixed scroll and orbiting scroll without the use of dynamic seals.

The patented liquid-cooled configuration relies on two cooling plates, cooling channels on the back of the fixed scroll and orbiting scroll, and flexible tubing to circulate coolant throughout the compressor during operation.

Coolant from the aftercooler enters the face of the compressor and circulates through cooling channels on the opposite side of the fixed scroll. Coolant is then transferred to the orbiting scroll using flexible tubing and circulates through cooling channels on the opposite side of the orbiting scroll. Coolant can also be transferred to the motor using a simple cooling jacket.

cooling.

Liquid-Cooled Scroll Technology

Advantages

With its numerous advantages, scroll technology continues to replace traditional reciprocating, diaphragm, and vane technology in a variety of applications.

Air Squared uses a non-contacting scroll configuration that requires zero lubrication – no contamination, no filter, no pump, just clean air without the impurities of oil.

Liquid-cooled scroll technology is considerably quieter and smoother than traditional reciprocating technology.

The scroll geometry delivers continuous flow and eliminates the need for valves, resulting in significantly less port pulsation and associated valve noise. The unique orbital motion is dynamically balanced, minimizing vibration and reducing rubbing velocity far below piston rings or vanes.

Additionally, because liquid-cooled scroll designs do not require ambient air to directly cool the fixed scroll and orbiting scroll, the housing is enclosed and fan noise is eliminating, reducing sound levels even below that of air-cooled scroll designs.

Air Squared uses a simplistic scroll design approach, with few moving parts and lightweight aluminum construction.

Additionally, because liquid-cooled scroll designs do not require ambient air to directly cool the fixed scroll and orbiting scroll, several auxiliary components (e.g., cooling fins, fans, ducting) are no longer necessary, allowing for a compact design with a minimal footprint.

Liquid-cooled scroll technology has minimal re-expansion losses – a problem found in reciprocating machines with every piston stroke – greatly improving volumetric efficiency. Throttling losses are also nonexistent with the valveless design.

Additionally, by introducing effective cooling directly to the fixed and orbiting scroll, internal running clearances can be reduced compared to air-cooled designs, significantly improving efficiency.

Liquid-cooled scroll technology allows all components to be arranged in an enclosed housing, providing ideal immersion protection for applications with harsh environmental conditions.

Liquid-cooled scroll technology is durable and robust, with 70% fewer moving parts than reciprocating technology. Liquid-cooling provides a thermal barrier between the compression process and bearings, significantly improving bearings life and with only two primary components, the design is highly reliable and easily serviceable.

Liquid-Cooled Scroll Technology

Learn More

Compared to air-cooled scroll compressor designs, liquid cooling offers superior isolation of working fluid to ambient and drive componentry (i.e., motor). Air-cooled compressors cool the fixed scroll and orbiting scroll with ambient air. While this approach is adequate with an open-housing compressor design, air cooling is far less effective if the compression process is fully enclosed (e.g., sealed or semi-hermetic). Liquid-cooling solves this issue by providing highly effective cooling to the fixed scroll and orbiting scroll, even if the compressor is semi-hermetically sealed.

Liquid cooling also operates independently of ambient conditions. This allows for effective cooling even if the compressor is exposed to elevated ambient temperatures – as in under-the-hood vehicle applications.

For operation with flammable gases, such as O2 and H2, the “independent drive” series of liquid-cooled scroll compressors are easily configured with a magnetic coupling that fully isolates the working fluid from the motor.

Air Squared has two primary drive configurations for liquid-cooled scroll designs.

INTEGRATED DRIVE

The integrated drive configuration uses a liquid-cooled BLDC motor. With liquid cooling available to the motor, as well as the compressor head, liquid-cooled scroll compressors with an integrated drive configuration are more efficient and compact.

With the cooling system fully integrated with both the motor and compressor head, custom motor requirements are difficult with an integrated drive configuration. Operation with flammable gases is also not recommended, as the motor is not isolated from the working fluid.

INDEPENDENT DRIVE

The independent drive configuration is ideal for customers with custom motor requirements or operation with flammable gases. The independent drive configuration removes all rotating radial loads on the motor bearings, leaving only the torque radial loads. This allows for flexibility in motor selection, as well use of a magnetic drive coupling that fully isolates the motor from the working fluid.

If your application requires an independent cooling loop, Air Squared offers integration of a single-phase liquid cooling loop, which includes all necessary hardware to circulate the coolant and discharge thermal energy.