Air Squared News

NASA Funds Multi-Stage Scroll Compressor Technology

Air Squared awarded SBIR Phase I funding to develop two scroll solutions that will support ISRU processes by collecting, separating, pressurizing, or processing gasses from the Mars atmosphere.

Broomfield, CO — Air Squared has been awarded Phase I Small Business Innovation Research (SBIR) funding through the National Aeronautics and Space Administration (NASA) under the topic Mars Atmosphere Acquisition, Separation, and Conditioning for In Situ Resource Utilization (ISRU). The SBIR award follows Air Squared’s work with the Jet Propulsion Laboratory (JPL) on the Mars Oxygen ISRU Experiment (MOXIE), which will send an Air Squared scroll compressor to Mars on the Mars 2020 rover mission.

NASA requires advanced technologies that support ISRU processes by collecting, separating, pressurizing, or processing gasses from the Mars atmosphere. ISRU is a critical component of future missions to Mars and an opportunity to significantly reduce the mass and cost of space exploration architectures. There are several ways to capture and pressurize carbon dioxide (CO2) from the Mars atmosphere, including freezing at cryogenic temperatures, mechanical compression, and absorption. Completed studies on each approach have generally favored cryogenic temperature and mechanical compression solutions. Recently, however, mechanical compression has gained momentum through MOXIE, which utilizes an Air Squared compressor for mechanical compression of CO2.

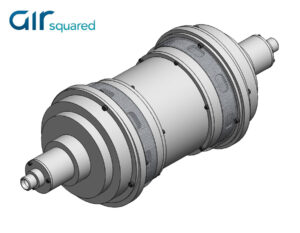

Air Squared has proposed using multi-stage scroll compressor technology. The technology has substantial improvements compared with state-of-the-art mechanical compression technologies, such as high-speed turbo-compressors. The size, weight, and power requirements are all reduced. Reliability is also improved, as multi-stage scroll compressor technology operates at significantly lower speeds than turbo-compressors. Additionally, multi-stage scroll technology has high dust tolerance (particulates larger than 50 μm) and robustness to harsh environments and includes an integrated filter on the discharge to remove dust and particulates before downstream processing. The technology requires only electric power (not thermal) and will utilize near-adiabatic compression to maintain high discharge temperature.

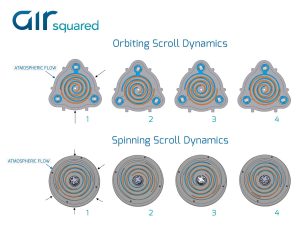

As part of the Phase I effort, Air Squared will develop two types of multi-stage scroll solutions, an orbiting scroll compressor, and a spinning scroll compressor. The orbiting scroll approach has one fixed scroll and one orbiting scroll, while the spinning scroll approach has two scrolls spinning in the same direction on an eccentric axis. The orbiting scroll solution will have the advantage of longer design heritage and lowers the associated risk, while the spinning scroll solution will have the benefit of achieving an aggressive size and weight target.

MULTI-STAGE SCROLL TECHNOLOGY

The purpose of the multi-stage scroll technology is to help reduce the overall footprint of the device, while providing the same performance, or better, of a single-stage device. Multi-stage technology can be configured to run in series, parallel, or both within the same unit.

The primary benefit of two-stage technology is that the device has the same number of moving parts as a traditional single-stage design. This is accomplished by machining an additional involute on the back side of the orbiting scroll and adding a mating scroll on the housing.

SPINNING SCROLL TECHNOLOGY

In principle, the design of the spinning scroll (also referred to as a “co-rotating scroll”) is very similar to that of the traditional orbiting scroll, as the relative motion between the two scrolls is identical. Pressure and flow are generated the same in both approaches, with the relative motion between the scrolls creating a series of crescent-shaped gas pockets that generate pressure, vacuum, or expansion depending on how the device is being operated.

The primary difference is that the traditional approach of one scroll remaining stationary while the other scroll orbitseccentrically on a fixed path is replaced with two scrolls that rotate in synchronous motion with offset centers of rotation.

The spinning scroll approach reduces componentry, improves efficiency, and allows for higher running speeds. The true rotary motion of the synchronous scrolls eliminates the need for counterweights, allowing for shorter and lighter drive shafts, which, in turn, reduce power consumption, size, and weight. The simplified balancing and a lighter drive configuration also allow for higher obtainable running speeds by a factor of two. As pressure and flow are directly proportional to speed, the spinning scroll design can offer a similar performance with substantial size and weight reduction.

ABOUT AIRSQUARED

Air Squared is the industry leader in oil-free scroll design and manufacturing. By introducing a simple design with fewer moving parts, scroll technology has established itself as a highly efficient, very reliable, cost-effective alternative. Through a growing line of compressors, vacuum pumps, and expanders, Air Squared makes the many advantages of oil-free scroll technology available to OEMs worldwide.

This material is based upon work supported by a Phase I SBIR award by the National Aeronautics and Space Administration under the topic: Mars Atmosphere Acquisition, Separation, and Conditioning for ISRU (H1.01). Any opinions, findings, conclusions, or recommendations expressed in this material are those of the author(s) and do not necessarily reflect those of the National Aeronautics and Space Administration.

UPDATE (May 21st, 2018) – Following a successful Phase I effort, Air Squared has been awarded Phase II SBIR funding from NASA.