Air Squared News

Development of CryoScroll™ Technology Continues With Funding Through NASA Award

Air Squared will develop an innovative and versatile cryogenic spinning scroll pump (CSSP) for in-space propulsion that is capable of pumping two-phase methane or oxygen over a wide range of speeds (1,000-8,000 RPM) and differential pressures, while maintaining high reliability and a compact footprint.

Broomfield, CO — Air Squared first applied its experience with scroll technology to cryogenic fluids with the development of the “World’s First Small-Scale Positive Displacement Cryogenic Pump” in 2014. Air Squared had identified cryogenic pumping technology as an area where the state-of-the-art could be challenged by an innovative solution derived from their long history of engineering custom scroll solutions for unique fluids. “Our primary goal with that first cryogenic scroll prototype was simply demonstrating feasibility, to show it’s possible,” says Bryce Shaffer, Chief Technology Officer at Air Squared. “We try to find areas where no one has tried anything new in a long time, then imagine a way scroll technology could challenge the status quo.”

While the initial prototype developed in 2014 was ultimately unable to demonstrate feasibility, a next generation cryogenic scroll pump developed for the Department of Energy (DOE) did. Using what Air Squared is now calling “CryoScroll™” technology, in early 2017 Air Squared demonstrated a positive displacement scroll pump that could pump multi-phase cryogenic liquid argon with a differential pressure of 50 psigat speeds around 1,000 RPM.

Air Squared is now looking to the aerospace industry to apply its CryoScroll technology. There are currently two vastly different technology options for pumping cryogenic fluids. The first option, and most common, is centrifugal or axial flow turbopumps. While turbopumps are compact and lightweight, high-speed operation limits life and makes handling two-phase flow difficult. The second option is positive displacement technology, which cannot achieve speeds over 3,000 RPM without bulky and high-load capability bearings, making positive displacement pumps larger, and consequently, less desirable for aerospace applications. A compact, reliable, and lightweight pump for cryogenic liquids currently does not exist, presenting a problem for the aerospace industry.

With Phase I SBIR funding from NASA, Air Squared will develop an efficient, compact, lightweight, reliable, electric-driven, cryogenic spinning scroll pump (CSSP) that is capable of pumping cryogenic liquid methane or oxygen. The CSSP will apply the same CryoScroll™ technology demonstrated for the DOE, but will have a spinning scroll configuration rather than a traditional orbiting scroll configuration. Spinning scroll technology is capable of operating much higher speeds (up to 8,000 RPM), allowing for a compact and lightweight cryogenic pump that does not sacrifice reliability or two-phase flow handling.

SPINNING SCROLL TECHNOLOGY

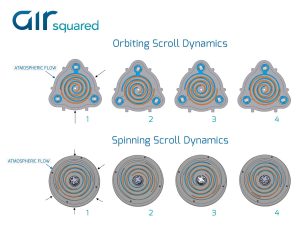

In principle, the design of the spinning scroll (also referred to as a “co-rotating scroll”) is very similar to that of the traditional orbiting scroll, as the relative motion between the two scrolls is identical. Pressure and flow are generated the same in both approaches, with the relative motion between the scrolls creating a series of crescent-shaped gas pockets that generate pressure, vacuum, or expansion depending on how the device is being operated.

The primary difference is that the traditional approach of one scroll remaining stationary while the other scroll orbitseccentrically on a fixed path is replaced with two scrolls that rotate in synchronous motion with offset centers of rotation.

The spinning scroll approach reduces componentry, improves efficiency, and allows for higher running speeds. The true rotary motion of the synchronous scrolls eliminates the need for counterweights, allowing for shorter and lighter drive shafts, which, in turn, reduce power consumption, size, and weight. The simplified balancing and a lighter drive configuration also allow for higher obtainable running speeds by a factor of two. As pressure and flow are directly proportional to speed, the spinning scroll design can offer a similar performance with substantial size and weight reduction.

ABOUT AIRSQUARED

Air Squared is the industry leader in oil-free scroll design and manufacturing. By introducing a simple design with fewer moving parts, scroll technology has established itself as a highly efficient, very reliable, cost-effective alternative. Through a growing line of compressors, vacuum pumps, and expanders, Air Squared makes the many advantages of oil-free scroll technology available to OEMs worldwide.

This material is based upon work supported by a Phase I SBIR award by the National Aeronautics and Space Administration under the topic: Methane In-Space Propulsion (Z10.02). Any opinions, findings, conclusions, or recommendations expressed in this material are those of the author(s) and do not necessarily reflect those of the National Aeronautics and Space Administration.

UPDATE (July 10th, 2018) – Following a successful Phase I effort, Air Squared has been awarded Phase II SBIR funding from NASA.