Air Squared News

All-Metal Scroll Pump Development Continues

The DOE has agreed to support the development of a liquid-cooled, all-metal scroll pump, with the ultimate goal of procuring a 150 m3/hr pumping capacity tritium pump.

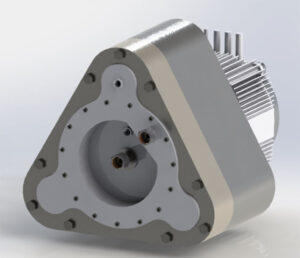

Broomfield, CO — Air Squared has been awarded Phase I Small Business Innovation Research (SBIR) funding through the US Department of Energy (DOE) under the topic Advanced Technologies and Materials for Fusion Energy Systems. The development is a continuation of an Air Squared internal development that resulted in an air-cooled, all-metal scroll pump with 15 m3/hr pumping capacity. The pump is compatible with virtually any working fluid on the planet, and through a partnership with Karlsruhe Institute of Technology (KIT), the pump will be tested using tritium at Tritium Laboratory Karlsruhe (TLK) in late-2017.

Air Squared has recognized a global need for an increased capacity pump that is capable of handling corrosive and radioactive gases such as tritium. Several companies and research institutes around the world (e.g. multi-national partnerships like JET, ITER, and DEMO) are actively searching for a tritium-compatible pump with 150 m3/hr pumping capacity, but significant technical challenges prevent Air Squared from simply scaling the current 15 m3/hr design to 150 m3/hr.

To avoid fluid compatibility concerns the all-metal scroll design has no tip seals between scroll involutes. Alternatively, involute tips are precision machined using state-of-the-art processes at Air Squared, resulting in running clearances between the scroll components that are as tight as currently feasible. With close clearance between involutes, thermal expansion of the involute material (i.e. stainless steel) becomes a significant concern. As the small-scale 15 m3/hr pump is already at the limit of air cooling effectiveness, a larger pump design will require a unique thermal management system. To solve this challenge, Air Squared intends to integrate a novel liquid cooling system in the 150 m3/hr capacity pump.

During Phase I, Air Squared will implement liquid cooling into the existing small-scale 15m3/hr design. The prototype should demonstrate improved performance over the air-cooled design, as liquid cooling allows for tighter running clearances that reduce leakage and improve efficiency. If successful, Air Squared will develop and prototype a full-scale 150 m3/hr pump as part of a Phase II effort.

About Air Squared

Air Squared is the industry leader in oil-free scroll design and manufacturing. By introducing a simple design with fewer moving parts, scroll technology has established itself as a highly efficient, very reliable, cost-effective alternative. Through a growing line of compressors, vacuum pumps, and expanders, Air Squared makes the many advantages of oil-free scroll technology available to OEMs worldwide.

This material is based upon work supported by the Department of Energy under SBIR Solicitation Number DE-FOA-0001417. Any opinions, findings, conclusions, or recommendations expressed in this material are those of the author(s) and do not necessarily reflect those of the Department of Energy.

UPDATE (October 10th, 2018) – After a successful Phase I effort, Air Squared was awarded Phase II SBIR funding to continue development. The Phase II effort will focus on development of a large-scale LCAM vacuum pump with 150 m3/hr pumping capacity and will be complete by 2020.