Staged Scroll Technology

Overview

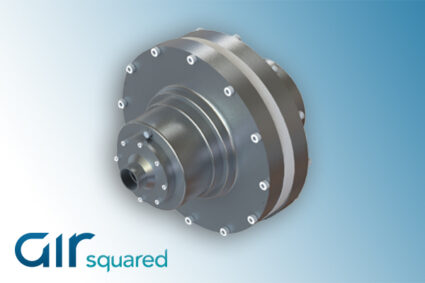

Staged scroll technology from Air Squared allows for high vacuum capability in a compact and lightweight design - ideal for applications with challenging size and weight requirements.

Modern innovation drives technological progress into an ever-shrinking footprint, continuously challenging pneumatic solutions to deliver better performance in less space. Staged scroll technology integrates two or more stages in a single compact housing, providing the deep vacuum capability of a multi-stage vacuum pump, without the added size and weight.

Range Technical Overview

Design Experience Range

Product Line Coverage

Staged Scroll Technology

How It Works

Design and Construction

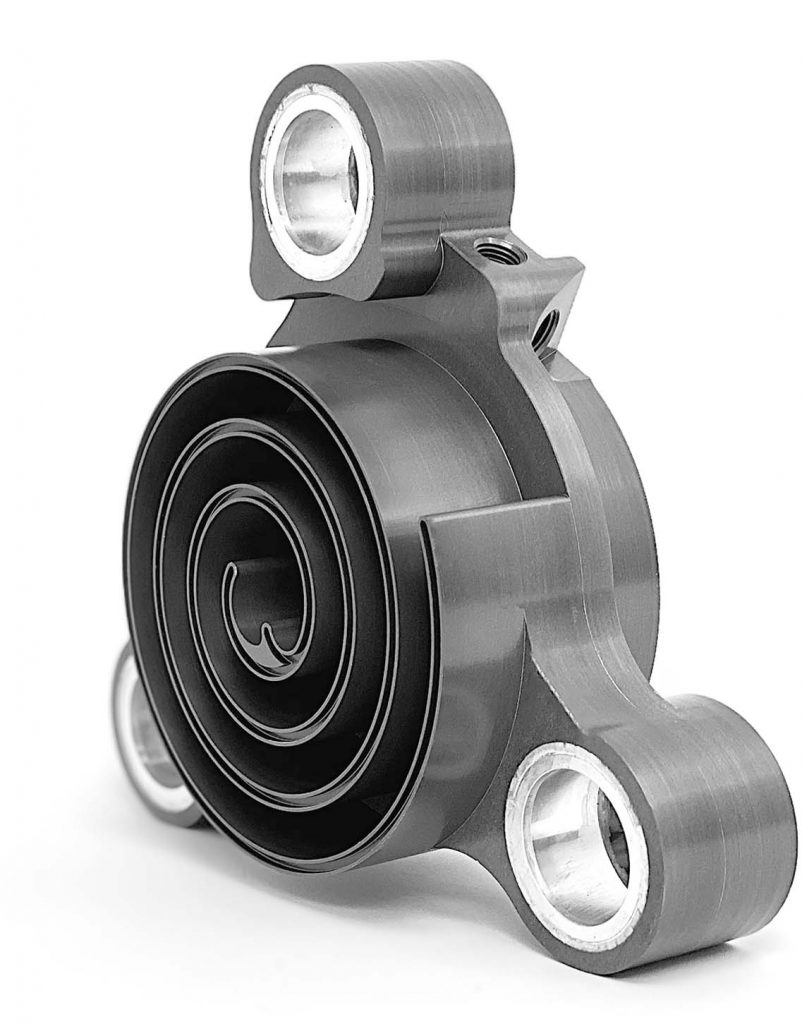

Staged scroll technology adds a second involute to the back of the orbiting scroll and a mating involute to the housing, packaging multiple stages (in series or parallel) in a single compact design.

All stages operate using a common crankshaft, motor, and housing, substantially reducing the size, weight, and componentry. The unique configuration can be used to create compact multi-stage scroll designs and each stage can be optimized based on the required displacement and required vacuum, compression, or expansion.

Using a single orbiting scroll to be used for two stages simultaneously removes redundant components between stages from the design, reducing overall footprint without sacrificing performance. The reduced part count also improves reliability, reduces cost, and reduces weight.

Staged Scroll Technology

Advantages

Staged scroll technology delivers high vacuum capability in a quiet and compact design.

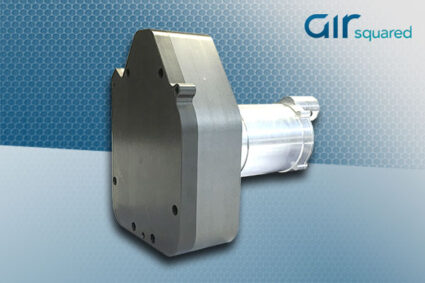

Air Squared uses a non-contacting scroll configuration that requires zero lubrication – no contamination, no filter, no pump, just clean air without the impurities of oil.

Staged scroll technology reduces overall footprint while providing the same performance or better than single single-stage designs.

Staged scroll technology has the same number of moving parts as a traditional single-stage design. The additional involute on the back of the orbiting scroll allows both stages to use a common motor and crankshaft.

Staged scroll technology is considerably quieter and smoother than traditional technology.

The scroll geometry delivers continuous flow and eliminates the need for valves, resulting in significantly less port pulsation and associated valve noise. The unique orbital motion is dynamically balanced, minimizing vibration and reducing rubbing velocity.